Dry Type Transformers

Dry Type Transformers

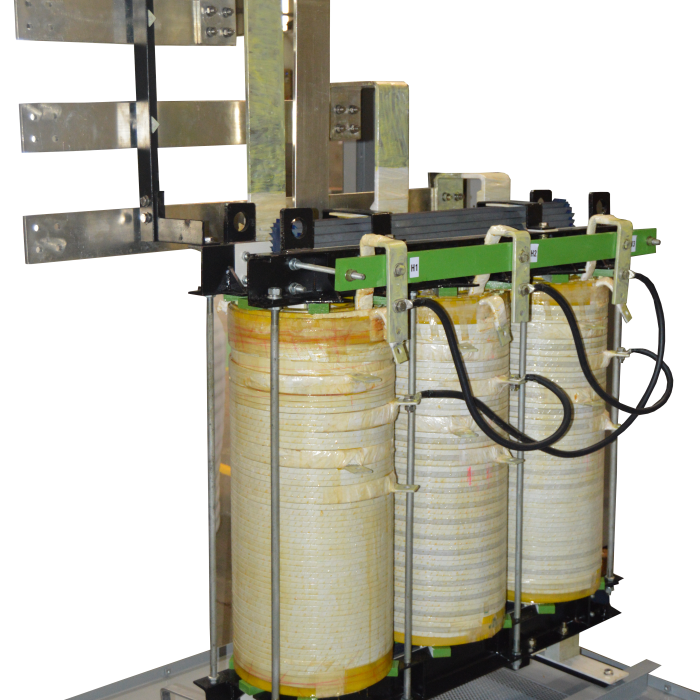

VPI / Cast Resin

5 Kva – 2.5 MVA , Up to 11 Kv Class

We manufacture Vacuum Pressure Impregnated Transformers with Conventional & Corrugated Enclosures as per Customer requirement. These Transformers are specifically needed in distribution networks for feeding basements or stilts of high-rise structures, Hotels, Air Ports , Residential Complex, Malls, stadium, chemical & refinery plants, Distribution Net works.

Previous

Next

A dry type transformer does not use a liquid cooling agent. Instead of oil, circulating air protects the coils – windings and insulation – from overheating. Within the transformer, manufacturers have multiple options for the components used for insulation, windings and core materials. The quality of materials and construction determine the operating temperature range and ultimately the useful life of a transformer.

Key Benefits

- Impregnation Process is Automatic & It Ensure a Void Free Insulation

- Multiple voltages on primary and secondary side to suit customer requirement

- Low voltage winding with high current taps provided

- Copper or Aluminium, Windings are electrically & precisely balanced to minimize axial & radial short circuit forces.

- Coils are kept rigidly in place between insulators clamped to the upper and lower core frame parts under high compression.

- High temperature resistant materials are used including Nomex Aramid papers, silicone coated fibre glass and pressure sensitive glass tape.

- Adequate ducts between coils, discs for maximum air circulation and reduced hot spot temperature.

- Self-extinguish type with higher resistance to fire than oil

- Suitable for harmonic loading.

- Step-lap designed CRGO laminations for lower losses and excitation current

- Fans can be used to upgrade the rating

Dry Type Transformer Applications

ATLAS dry type transformers provide efficient and reliable power to the following industries:

Previous

Next