Distribution Transformers

Distribution Transformers

10 KVA – 5 MVA ( up to 33 Kv Class )

A Distribution Transformer is a transformer that provides the final voltage transformation in the electric power distribution system, stepping down the voltage used the voltage used in the distribution lines to the used by the customers.

Features of BIS-1180

We Manufacture BIS approved distribution transformer starting from 10 KVA to 2500 KVA under BIS-1180(Jan 2016) of all voltage class and covering all level of efficiency.

Distribution transformer has two different variant offload distribution transformer and onload distribution transformer.

Offload Distribution Transformers:

We manufacture ISI approved offload distribution transformer starting from 10 KVA to 2500 KVA under BIS-1180 (Jan 2016) and above 2500 KVA up-to 5000 KVA under IS-2026 of all voltage class and covering all level of efficiency.

Designed for minimum 25 years for 24 x 7 duty with negligible maintenance and silent operation.

Indoor/ Outdoor pad Mounted.

Copper Winding with multiple paper covering.

Features of Off Load Transormer

Type

Indoor /Outdoor pad Mounted

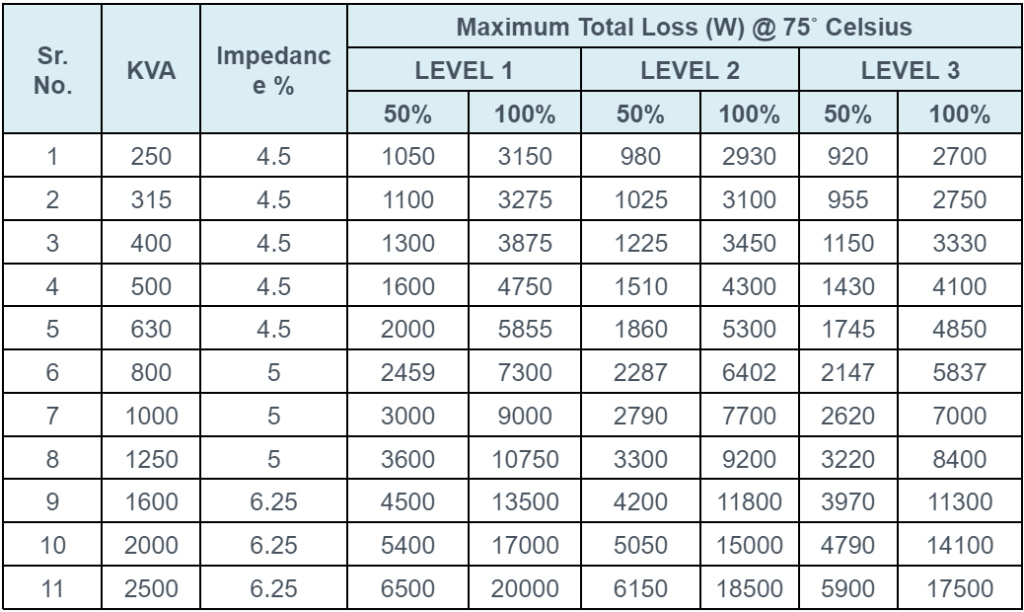

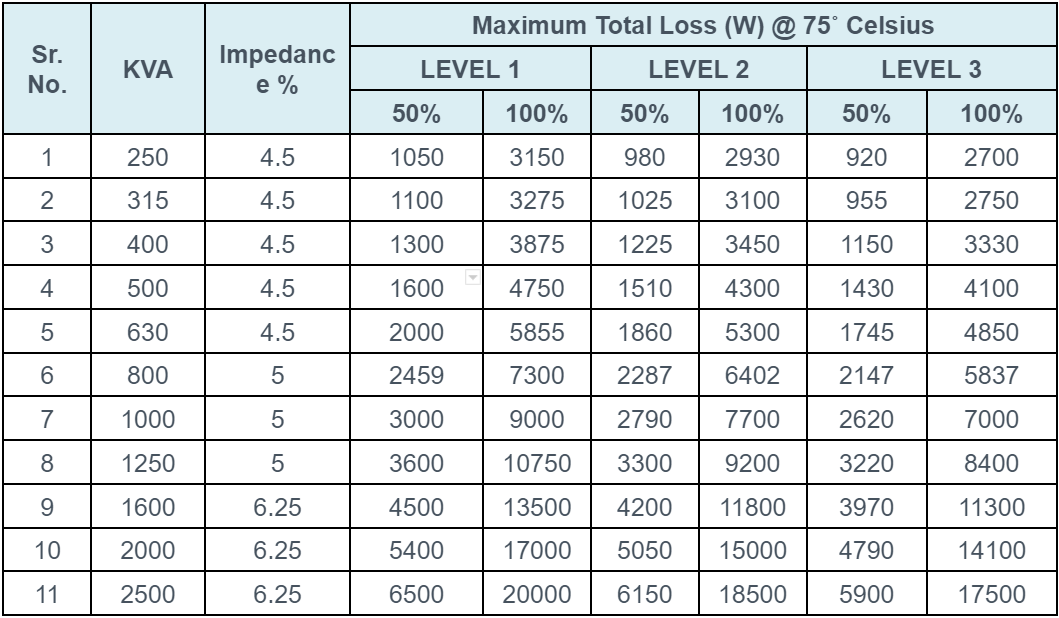

Maximum Total Losses Upto 11 kV Class Transformers As Per BIS-1180

SERVING INDUSTRIES!!

ON Load Distribution Transformers:

We manufacture ISI approved on load distribution transformer starting from 200 KVA to 2500 KVA under BIS-1180( Jan 2016) and above 2500 KVA up-to 5000 KVA up-to 5000 KVA under IS-2026 of all voltage class and covering all level of efficiency. Designed for minimum 25 years 24 x 7 duty with negligible maintenance and silent operation. Indoor/ Outdoor pad Mounted. Copper Winding with multiple paper covering.Features of On Load Transformer:

Magnetic circuit is made using step-lap design for lower losses and law magnetising current of core by using high quality CRGO material with grades such as ZDKH, ZDMH, AMORPHOUS, MOH, Etc. Electric Circuit is made using electrolytic grade with 99.99% pure High Quality Copper from our regular and reputed vendor HINDALCO & STERLITE with Foil winding in LV coil of transformer. High Dielectric insulation property to withstand lightening impulse and voltage surges. ONAN through natural convection for effective cooling through axial and radial ducts.TECHNICAL SPECIFICATION:

On load Transformers are installed where voltage fluctuations from h.v side are continuous. So onload transformer changes tap using AVR without any power-cut and give constant output voltage. Thus over –all power consumption of industry gets optimised hence results in power savings.Technical Specification

Type

Indoor /Outdoor pad Mounted

STANDARD FITTING

- Rating & Diagram Plate

- Earthing terminals

- Lifting Lugs

- Thermometer Pocket

- Air Release plug

- Conservator Tank

- Cover Mounted Thermometer

- Oil level indicator

- Explosion vent with suitable Diaphragm

- Drain cum Oil Filter valve

- Top Oil Filter valve

- Bi-Directional Roller

- Silica gel breather

- Cooling Radiators

- H.V & L.V Side cable box with copper bus-bar

- Neutral – earth bushing for earthing of neutral

- RTCC panel for onload distribution transformer

PROTECTIVE DEVICES:

- Buchholz Relay with alarm and trip contact for transformers from 500 KVA to 5000 KVA

- Oil Temperature Indicator with alarm and trip contract for transformers from 630 KVA to 5000 KVA

- Winding Temperature Indicator with alarm and trip contact for transformers from 800 KVA to 5000 KVA

- Magnetic Oil Level gauge with alarm contact for transformers from 1250 KVA to 5000 KVA

OPTIONAL ACCESSORIES:

- Neutral C.T

- Jacking Pads

- Shut –off Valves

- Annunciation / Inspection Window

- Pressure Release value with contacts

TYPE OF WINDING

For achieving losses as per BIS-1180 we have developed FOIL WINDDING for LV coil of the transformer, Following are main advantages of foil winding.

Temperature rise is lower due to high face-area for current flow.

High Mechanical strength towards AXIAL and RADIAL forces in comparison to conventional layer winding.

No need of transposition due to foil winding which gives exact results as compare to conventional winding.

Inter-turn Fault is vanished out due to foil winding as compare to layer winding.

BENEFITS:

Due to on-load transformer the voltage at LV side remains in limit against the voltage fluctuations from HV side.

For changing a tap, shut down of factory is not reliable. But due to the on-load transformer, you can change tap even when your factory is running.

Due to on-load transformer efficiency of transformer increases, losses of the transformer and other electrical equipment decreases results in low power consumption, and overall life of the transformer and other electrical equipment increases.

Maximum Total Losses Upto 11 kV Class Transformers As Per BIS-1180